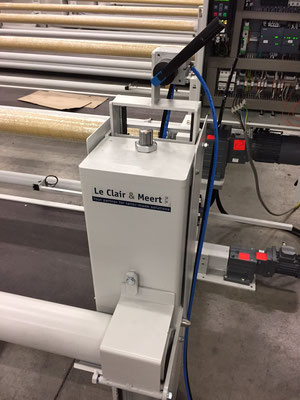

Backing unwinders

Feeding your primary backing to your tufting machine in a controlled way.

Our primary backing unwinder feeds your backing to the tufting machine in a controlled way to optimise your quality.

We controll the position and tension of the backing before going to the machine to ensure it always goes in the same place and with the same tension to your tufting process.

Drive + Tension:

With our backing unwider, yourprimary backing is fed in a positive way to your machine instead of pulled by the tufting machine.

The rubber coated roller is driven by a servo motor. The speed of the roller is controlled by the position of the dancing roller. By this setup, we ensure equal tension of the cloth during your tufting process.

Position:

The position of the backing going into the machine is adjusted by moving the whole feeding device with platform to left or right. This ensures you that the backing is not shifting in your tufting machine.

The motion is limited by limit switches.